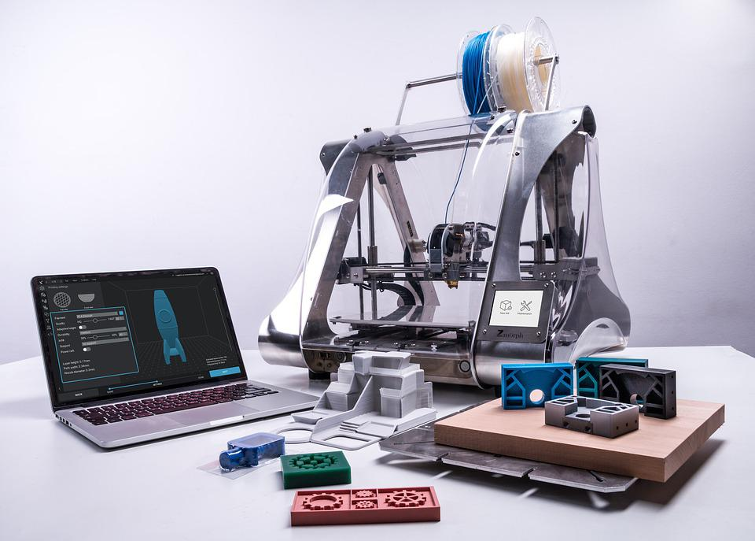

Additive manufacturing (AM), also known as 3D printing, is one of the fastest-developing manufacturing technologies in the world. It is a process of layer-by-layer material deposition to produce parts from 3D models. 3D printing has proven its effectiveness, especially in low-volume, high-customisation sectors such as aerospace for a variety of reasons. In this article, we will explore ways in which 3D printing can benefit all sectors, improve lead times and reduce costs. The focus will be on Fused Filament Fabrication (FFF) technology, in which a semi-fused plastic filament is extruded through a nozzle, but these principles can be applied generally to all printing technologies.

According to the 3D printing expert Edoardo Pruneri (from 4m group where he works as Consulting and Professional Service Manager) there are 5 good reasons to choose this new frontier of technology, let’s see them together.

1 – Freedom from manufacturing complexity.

In traditional manufacturing, the more complicated the object to be produced, the more expensive it is to obtain it. With 3D Printing, complexity is the same price as simplicity! Producing a complex, frilly shape requires no more time, knowledge and money than printing a block of comparable size. This freedom is bringing about a revolution in the pricing model and the way the costs of manufactured goods are calculated.

2 – Freedom to vary.

A single 3D printer can produce any shape. Like a good craftsman, a 3D printer can produce a different shape every time. Traditional machine tools are much less versatile and can produce objects in a limited spectrum of shapes. 3D printing removes the extra cost of retraining personnel and upgrading machine tools. A 3D printer only requires a different 3D model to be printed and a new load of raw material (filament).

3 – Ready-made assembly.

3D printing makes parts that are already assembled together. Mass production (cars, smartphones, etc.) is built around the backbone of assembly lines. In today’s factories, machine tools produce individual objects all the same, which are then assembled by human personnel or robots, sometimes on a different continent. The more parts the finished product contains, the longer it takes to assemble and the higher the cost of final production. By making objects in layers, a 3D printer could print a door with the hinges already fitted, at the same stage and without assembly afterwards. Fewer assembly operations mean a shorter supply chain, saving money, labour and transport, as well as being more sustainable for the environment

4 – No technical waiting time.

A 3D printer can print ‘on-demand’, starting production the moment the object is requested. The ability to produce on-demand reduces the need to maintain a stock of ready-made objects. This freedom opens up new business models for the production of special or customised components in rapid response to customer needs. This also reduces the need to produce far away, in factories the size of cities, wasting natural resources and pollution.

5 – Infinite possibilities of imagination.

Traditional production technologies and even the best craftsmen (with all due respect!) draw from a large but finite repertoire of forms. This is because our ability to make shapes is limited by the tools we possess/that are available. A lathe generally only makes cylindrical or conical shapes, a milling machine can only make shapes that are accessible from the tool, and a mould can only produce shapes that can be extracted from the mould form. 3D Printing removes these barriers, opening up virtually infinite possibilities. A printer can produce shapes that until now have only been possible in nature.

Sources:

I 10 principali vantaggi della stampa 3D | 4m group

Benefici e vantaggi della stampa 3D (roboze.com)

Stampa 3D in azienda: i quattro benefici reali e dimostrati (con casi applicativi) – Agenda Digitale